As a professional milling machine overall solution provider, CLIRIK has always focused on the research and development, production and sales of milling machinery and a complete set of milling production lines. The pumice powder milling production line was launched by CLIRIK for the current booming pumice powder application market Under the severe test of practical application, the pulverized powder production line shows a strong application value. It can help the large-scale and refined production of pumice powder. It is an ideal equipment to increase the added value of pumice powder products and promote the development of the industry. This article will introduce the price and working principle of a set of pumice powder production line.

1. Pumice powder grinding production line

Pumice (pumice) is a porous and light acid volcanic volcanic eruptive rock. It has the advantages of light weight, high strength, acid and alkali resistance, corrosion resistance, no pollution and no radioactivity. It is an ideal green and environmentally friendly product and is widely used. It has good market application value in construction, textile, clothing (rinsing, printing and dyeing) and other fields.

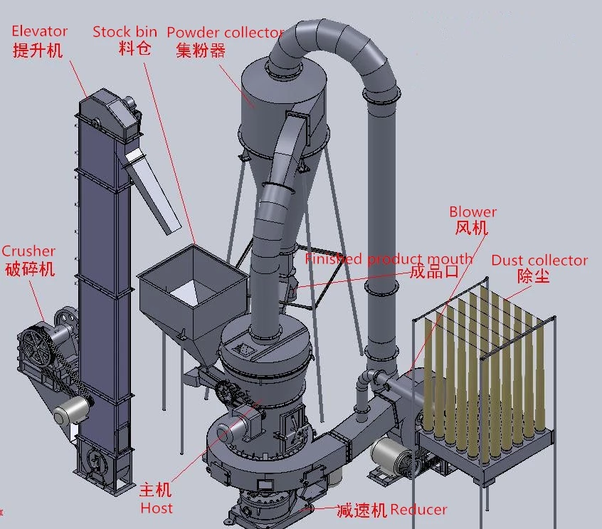

Pumice powder grinding production line, the main equipment includes: crusher, conveying equipment, pumice powder milling machine, fan, pulse dust collector, collection system, packaging production line (palletizer), under the background of more emphasis on systemization , CLIRIK also puts forward higher requirements for the system operation of the pumice powder milling production line, and the synergy between the equipment has been significantly improved.

2. Working principle of pumice powder grinding production line

To ensure that the entire pumice powder production line can maintain stable operation and obtain good output, the performance of the pumice powder production line is particularly important. CLIRIK has invested a lot of effort and invested a lot of manpower in the development of the pumice powder production line. Material resources, to innovate the working principle of the milling production line to make it more in line with the actual production needs of customers.

The pulverizer adopts a standardized modular design and manufacturing pressurizing device. As the capacity of the pulverizer increases, the number of rollers of the vertical pulverizer is increased accordingly. 2 rollers, 3 rollers or 4 rollers can be used. The 6 grinding rollers are arranged and combined to form the production capacity for producing a variety of products with the minimum standard modular components to meet the requirements of different product fineness and output.

The motor drives the reducer to drive the grinding disc to rotate. The material moves around the grinding disc and enters between the grinding roller and the grinding disc under the action of centrifugal force. Under the pressure of the grinding roller, the material is crushed and crushed by the extrusion, grinding and shearing forces. The powder is blown by the airflow of the blower to the classifier above the main machine for sieving. The coarser particles still fall into the main machine for regrind. The fineness meets the specifications and flows into the pulse dust collector with the wind. After collection, it is discharged through the powder outlet. The finished product, the purified airflow flows into the blower through the pipeline on the pulse collector and is discharged into the atmosphere.

3. Pumice powder production line price

In terms of price, CLIRIK is fully based on the market and customer needs, and the price of pumice powder production line also follows this feature. Taking the important equipment in the pumice powder milling line-pumice powder mill as an example, CLIRIK has a variety of pumice powder mills, and at the same time, according to the individual needs of customers in terms of production capacity, particle size and moisture The parameters of the pumice powder mill are tailored, the number of grinding rollers is increased, and the model parameters of the classifier are configured accordingly. The resulting pumice powder mill achieves the optimal configuration in terms of configuration. Reduce unnecessary equipment expenditure and become more targeted and cost-effective.

Customers choose the CLIRIK pumice powder production line, which means that customers can purchase products with superior performance and reasonable professional after-sales service at reasonable prices. Therefore, Shanghai Clirik Machinery Co., Ltd has become the first choice for many companies to configure pumice powder production lines. If you want to know more related information, welcome online consultation, we will serve you wholeheartedly.