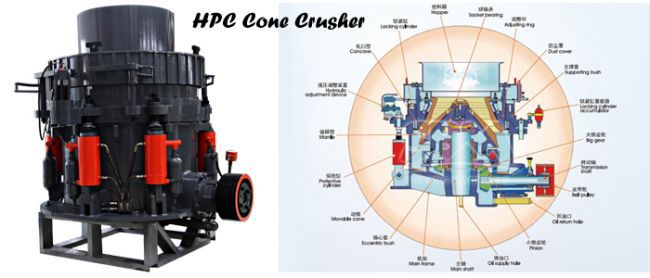

Product Introduction

Hydraulic cone crusher advantages:

1.Advanced disign.

2.All hydraulic operation.

3.Robust and reliable design for hard stone crushing.

4.High reduction efficiency with lowest total cost.

5.Easy operation and simply maintenance.

Hydraulic cone crusher application:

Secondary and tertiary crushing:

1.mining 2.aggregate 3.metallurgy 4.industrial 5.construction

Hydraulic cone crusher technical parameters:

| Model | Cavity | Discharge Opening(mm) | Max Feed Size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) | Overall Dimensions(mm) |

| EP155B | standard super coarse type | 25-64 | 220 | 236-455 | 160 | 23 | 2790*2415*3240 |

| standard coarse type | 19-51 | 205 | 172-378 | ||||

| standard medium type | 16-38 | 175 | 132-255 | ||||

| standard fine type | 13-31 | 115 | 109-181 | ||||

| EP155D | short head super coarse type | 16-25 | 110 | 209-236 | |||

| short head coarse type | 8-25 | 90 | 109-227 | ||||

| short head medium type | 6-16 | 75 | 82-163 | ||||

| short head fine type | 3-16 | 55 | 36-163 | ||||

| EP240B | standard super coarse type | 38-64 | 313 | 538-743 | 250 | 45 | 3640*2954*3770 |

| standard coarse type | 25-64 | 228 | 354-610 | ||||

| standard medium type | 22-51 | 205 | 258-437 | ||||

| standard fine type | 15-38 | 178 | 181-327 | ||||

| EP240D | short head super coarse type | 13-25 | 113 | 253-336 | |||

| short head coarse type | 20-25 | 113 | 190-336 | ||||

| short head medium type | 6-19 | 76 | 136-281 | ||||

| short head fine type | 5-13 | 60 | 90-209 |

Packaging & Shipping

Packaging: Conventional Packaging suitable for long distance transportation.

Shipping: 10-30 working days after receiving the deposit of the devices.

Our Service

Pre-sales Service: Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment, optimized process configuration and a full range of technical support.Every customer has the chance to visit the working machine in the site before placing the order,we help to arrange cars, hotels, and translators for every visiting customer.

After-sales Service: Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the calcium carbonate powder site to help install the customers' plants. Necessary training about machinedaily maintenance to local workers is provided also.

Our Company

As a leader enterprise which is specializing in research, manufacture and sales all kinds of mining equipment, We have many agents that sell our products all over the world.Our products are widely used in the industry of mining, construction materials, chemical, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM hydraulic cone crusher, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. We'll always follow your steps, pursue your value and achieve your profit.

Our Certifications

FAQ

1. What advantages does your hydraulic cone crusher have?

—The main advantage of our hydraulic cone crusher over other kinds of mills is that you can grind a friable or crystalline material to 5 – 47 microns average particle size and classify in a very narrow particle size range at the same time. There are no moving parts to wear out or generate heat in our mill and no screens to plug or be punctured.

2. Can you guarantee the quality of your hydraulic cone crusher?

—We have passed CE&ISO9001:2008, and our crushers have been exported to Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, America, etc.

3.How many years have you been manufacturing the machine?

—8 years. Since the foundation of our company, we have been manufacturing the machine, which updated many times, now the machine runs stable and of high quality

4. How do you adjust particle size in your hydraulic cone crusher?

—Particle size is adjusted primarily by a change in feed rate. When the rate is reduced, finer particles result because there is more energy available per particle to accelerate the particles and the entire fluid mass. Collisions become more violent and pressure gradients become larger.

Inquiry service

More details we needed for sending you more suitable quotation.

1. what kind of raw material do you want to process?

2. what is the capacity per hour do you need?

3. what is the raw material input size?

4. what is the finished size you required?

Any inquiries of our hydraulic cone crusher will be highly regard and we will give you the best quotation ASAP. Your satisfaction is our final and forever pursuit.

Please fill in your need products and your message and do not forget email and/or phone if you like to be contacted.

We are looking forward to your inquiries!

Hot Sale