In order to better develop and utilize local limestone resources, the advantages of limestone resources are transformed into economic advantages. Shanghai Clirik uses its own jaw crusher, hammer crusher, HGM series superfine pulverizer, three-ring medium-speed superfine pulverizer and other equipment, which is close to the limestone development front and is fully quoted in limestone crushing production. .

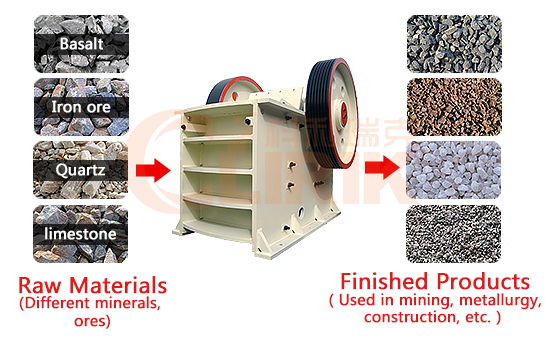

The jaw crusher is mainly composed of a fixed jaw and a movable jaw. The working principle is that the movable jaws periodically reciprocate the fixed jaws, and the stone is crushed between the two jaws. It can break the stone with higher hardness and larger particle size, but the discharge particle size is larger. Generally used as a rough cut of stone.

The hammer crusher is mainly composed of a suspension hammer and a turntable. The working principle is that the hammer is freely suspended on the turntable, and is rotated by the fast rotating turntable, and the stone is hit by the rotating hammer. It is suitable for the fine crushing of medium hard stone, which is characterized by low mechanical cost and high production efficiency. However, the crushed gravel has a high content of flakes and is not suitable for use in high-grade highway projects.

The vertical impact crusher is mainly composed of a rotor and a fixed plate hammer. The working principle is that the stone is crushed by the impact and extrusion of the rotor and the fixed plate hammer which are rotated at a high speed. It is suitable for medium and fine crushed hard stone processing, the crushing is relatively large, and the broken stone material has a uniform particle size. But the production cost is higher.

The impact crusher is mainly composed of a rotor, a plate hammer and a counterattack plate. The working principle is that the stone material is crushed by a high-speed rotating plate hammer, and the fly-off impact is further broken by hitting the counterattack plate. It is suitable for finely divided medium hardness stone. The aggregate size of the broken aggregate is uniform and close to the cube, and the needle-like content is small.

Shanghai Clirik Machinery Co., Ltd. will continue to innovate in response to market development needs, make a fuss about improving quality and structural transformation, continuously accelerate the pace of product structure optimization, and introduce the market demand that is adapted to the integration of mineral resources. The product structure has been expanded, and the hydraulic crushing machine mobile crushing machine has been developed. The broken crusher, the cone breaking mobile crusher, the impact breaking mobile crusher, the moving screening machine, the hydraulic sand making machine fixed crusher, the broken crushing machine Machine, cone broken fixed crusher, impact broken fixed crusher, etc. Mainly to the series of products, to the mid-to-high-end sales model, increase the thickness of the Collier machine brand, fully reflect the product value, and simply focus on sales growth Move to a rich product brand to ensure that the mid-range and above products are on the new sales target.