Product Introduction

Fluorite, also known as fluorspar, is a mineral whose main component is calcium fluoride (CaF2), which contains more impurities. Fluorite has a wide range of uses and plays a decisive role in the metallurgical and chemical industries. The use of decorative materials cannot be ignored.

Fluorite performance

Fluorite has a very low refractive index and no radioactivity, so the color of fluorite is very rich. Except for red and black, almost any other color can be seen. Because its crystal clear is like crystal, but the hardness is lower than crystal, so fluorite is also called soft crystal, colorful gemstone, rainbow gem and so on.

Use of fluorite

1. Fluorite has the characteristics of reducing the melting point of refractory substances, promoting the flow of slag, separating slag and metal well, desulfurization and dephosphorization during smelting, and enhancing the calcinability and tensile strength of metals. Therefore, it is widely used as a flux in steel smelting and ferroalloy production, iron processing and non-ferrous metal smelting.

2. Transparent, colorless fluorite can be used to make special optical lenses.

3, fluorite is also used to make opal glass, enamel products, catalysts in the production of high-octane fuel.

4, fluorite is also widely used in glass, ceramics, cement and other building materials industries.

5, fluorite often bright colors, so often made into a variety of jewelry. In fact, the night pearl we often see is the material of fluorite. Because of the special effect of fluorite, the energy is soft and soft, which can help alleviate the violent skin, reduce mental stress and eliminate work stress. Therefore, it is especially suitable for people who are more impulsive and have poor control ability.

6, the most important use of fluorite is the production of hydrofluoric acid, half of the world's fluorite production to produce hydrofluoric acid. Hydrofluoric acid is a key raw material for the production of various organic and inorganic fluorides and fluorine. In the aluminum industry, hydrofluoric acid is used to produce aluminum fluoride, artificial cryolite, sodium fluoride and magnesium fluoride.

7. In the aerospace and aerospace industries, hydrofluoric acid is mainly used to produce jet liquid propellants and missile jet fuel propellants. In the atomic energy industry, hydrofluoric acid is mainly used to make UF4, which is then fluorinated to form UF6, and 235U is separated by gas diffusion or gas centrifugation.

8. Hydrofluoric acid is the basic raw material of organic fluorine chemical. It interacts with chloroform and carbon tetrachloride to produce fluorinated chlorocarbons and fluorocarbons with low toxicity and high chemical stability. It is used as a refrigerant and air. A sol accelerator, an intermediate of a solvent polymer, and a fluorocarbon resin and an elastomer.

9. In medicine, fluoroorganic compounds can also produce fluorochemical anticancer drugs, fluorocortisone, fluorocarbon artificial blood, artificial heart and bone.

10. Fluorite is the most common processing material. The fluorite powder processed by fluorite mill is used in the fields of chemical industry, rubber, ceramics, construction, building materials, etc., and ultrafine fluorite powder after high-efficiency micro-powder milling machine. It is widely used in high-tech technology industries such as military cable, fiber transmission and high-precision smelting industry.

Precautions

Because the hardness of fluorite is low, don't put it together with natural crystal when wearing fluorite jewelry. Crystal will scratch fluorite, and the fluorite collected directly from the mine has certain radiation, it is best not to place it. bedroom.

The main use of fluorite powder:

Application areas: metallurgical industry ironmaking, steel and iron alloy flux, slagging agent, the production of artificial cryolite raw materials. Cryolite is used as a fluxing agent in the production of electrolytic aluminum, a brightener for enamel, an opacifier for glass, a chemical raw material for the production of anhydrous hydrofluoric acid, a fluorine chemical (Freon, a fluoropolymer, a fluorine-containing fine chemical). The raw material cement industry produces cement clinker mineralizer, which can reduce the sintering temperature, easy to calcination, short firing time, save energy glass industry to produce emulsified glass, opaque glass and colored glass raw materials, which can reduce the temperature of glass melting. Improve the melt, accelerate the melting, and thus reduce the fuel consumption ratio. The ceramic industry manufactures ceramics, enamel process fluxes and opacifiers, and is one of the indispensable ingredients for the preparation of glaze.

Fluorspar grinding equipment 200-400 mesh micronizer

Fluorite Raymond mill working process:

The whole structure of fluorite Raymond mill is composed of main machine, analysis machine, pipeline device and blower. It can be equipped with crusher, hoist, electromagnetic vibrating feeder and electronically controlled motor according to user needs. After the material is pulverized to the required particle size, the material is sent to the storage hopper by the hoist, and then the material is uniformly and continuously fed into the main machine grinding chamber through the vibrating feeder, and the grinding roller swings outward due to the centrifugal force during rotation. In the grinding ring, the blade shovel the material between the grinding roller and the grinding ring, and the grinding roller achieves the purpose of pulverizing. The fine powder after grinding of the material is brought into the analysis machine for sorting with the circulating wind of the blower, and the finely coarse material falls back to the regrind, and the qualified fine powder enters the finished cyclone powder collector with the airflow, and is discharged through the powder discharging tube. It is the finished product. In the grinding chamber, there is a certain amount of moisture in the material to be ground, heat is generated during grinding, water vapor evaporates, and the pipelines of the whole machine are not tightly connected, the outside air is sucked in, the circulating air pressure is increased, and the mill is operated under negative pressure. The increased air flow is discharged into the dust remover through the residual air duct, and is purified and discharged into the atmosphere.

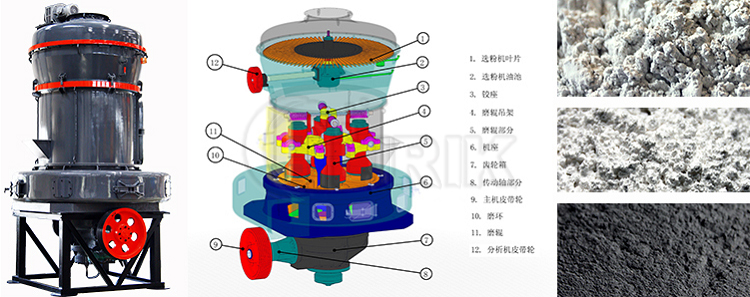

Fluorite Raymond mill structure

1. The three-dimensional structure of Raymond mill has a small footprint and a complete set of components. It is a self-contained production system from block to finished powder.

2. The fineness of the finished powder is uniform, and the screening rate is 99%, which is difficult for other milling equipment.

3. The main gear of the mill main machine adopts a closed gear box and pulley, which makes the transmission stable and reliable.

4. The important parts of Raymond mill are made of high-quality steel, and the wear parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

5. The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation and convenient maintenance.

Fluorite Raymond Mill Maintenance and Maintenance:

1. During the use of Raymond mill, there should be fixed personnel responsible for the inspection, and the operator must have a certain level of technology. Before the installation of the mill, the operator must carry out the necessary technical training to understand the principle performance of the mill and familiar with the operating procedures.

2. In order to make the Raymond mill normal, the equipment “safe operation system for equipment maintenance” should be established to ensure the long-term safe operation of the mill, and necessary maintenance tools as well as grease and corresponding accessories.

3. After using the Raymond mill for a period of time, it should be repaired and repaired. At the same time, the wearing parts such as the grinding roller and the blade should be repaired and replaced. The grinding roller device should be carefully checked before and after use to see if it is checked. There is looseness, and the grease is added.

4. When the grinding roller device is used for more than 500 hours to replace the grinding roller, the rolling bearings in the roller sleeve must be cleaned, and the damaged parts should be replaced in time. The fueling tool can be manually pumped and greased.

Fluorite Raymond mill models:

3R2115, 3R2615, 3R2715, 3R3016, 4R3216, 5R, 6R, 7R.

| Type | Roller | Max. feeding size(mm) | Fineness of product(mm) | Output (t/h) | Power of machine(KW) | Size(mm) | ||

| No. | Dimension(mm) | Height(mm) | ||||||

| YGM7815 | 3 | 260 | 150 | 15 | 0.613-0.033 | 1-3 | 18.5 | 4300*3500*5100 |

| YGM8314 | 3 | 270 | 140 | 20 | 0.613-0.033 | 1.2-4.6 | 22 | 5300*4100*5200 |

| YGM9517 | 4 | 310 | 170 | 25 | 0.613-0.033 | 2.1-5.6 | 37 | 7100*5900*7900 |

| YGM4121 | 5 | 410 | 210 | 30 | 0.613-0.033 | 2.8-10.5 | 75 | 9200*7250*9700 |

| MTM1600 | 6 | 440 | 270 | 35 | 0.613-0.033 | 5-20 | 132 | 12550*5700*8350 |

Notice: Any change of Raymond micronizer mill technical data shall not be advised additionally.