Calcium carbonate micronizer mill also named calcium carbonate micronizer machine,there are many types of micronizer mills,today we will talk two of these micronizer machines working principle:ring roller micronizer mill and high-pressure micronizer mill

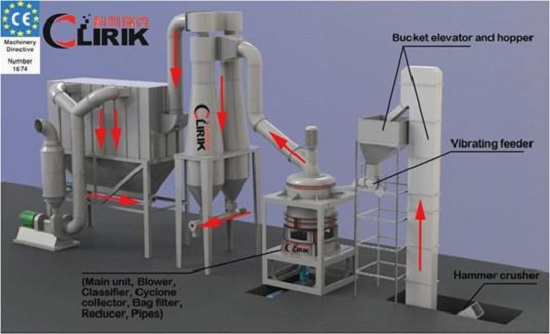

The ring roller micronizer mill main motor drives the main shaft and each layer turntable through the reducer, and the turntable drives dozens of ring rolls to roll and rotate in the grinding ring raceway through the pin. The bulk material is broken into small particles by a hammer crusher and then sent to the storage bin by the hoist. The electromagnetic vibrating feeder sends the material evenly to the middle of the upper turntable, and the material is scattered to the circumference of the circle under the action of centrifugal force. It falls into the raceway of the grinding ring of the ring roll micronizer machine and is crushed by rolling and grinding.

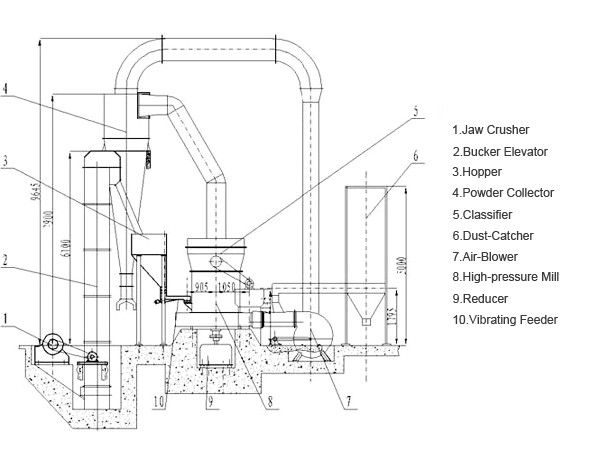

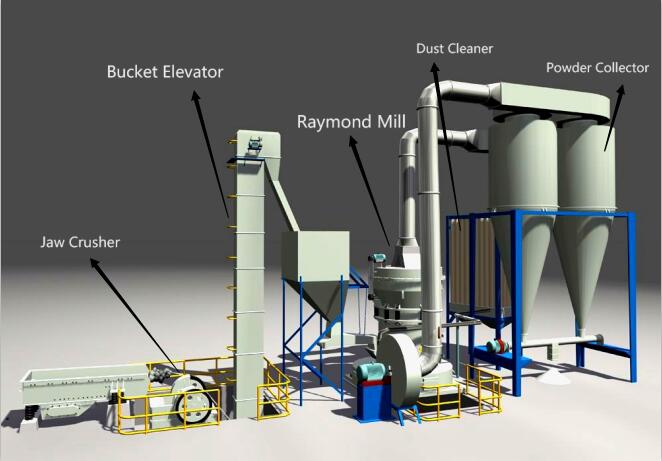

The principle of the high-pressure micronizer mill is that the material to be pulverized is fed into the machine from the inlet of the main machine, and is rotated around the vertical axis by the grinding roller device, due to the centrifugal force generated during the rotation. The grinding roller swings outward and is pressed against the grinding ring. The material is finally crushed and squeezed between the grinding roller and the grinding ring. According to the customer's requirements, the pressure of the grinding roller on the grinding ring is appropriately adjusted, and finally the material is crushed to the desired particle size. . Such a working principle is prone to high noise, and the wear of the grinding roller is too large, belonging to the grinding on the inner wall surface of the grinding ring. .

The internal material of the micronizer machine is ground on the nominal curved loop inside the grinding ring, and the material is crushed by the first layer and then falls into the second layer and the third layer. The suction of the high-pressure centrifugal fan takes the outside air. Inhaled into the machine, and the coarse powder after the third layer is pulverized into the classifier. The vortex generated by the rotating turbine in the classifier causes the coarse-grained material to fall back to re-grind, and the fine powder enters the cyclone collector with the airflow and is discharged by the discharge valve at the lower part thereof. There are no bolts and bearings inside the main unit, and there is no phenomenon that the finished product exists in the medium.

The high-pressure micro-powder mill has a high-pressure device, and the grinding roller of the ring-roller micronizer mill is annular. Ultra-fine micronizer mill wear parts have low loss. All wearing parts are made of high-quality wear-resistant materials at home and abroad, which are longer than the wear parts of ordinary mill equipment, and can generally last for more than one year. There are no rolling bearings and no screws in the grinding chamber. There are no problems such as the bearing and its seals and the fragile screws are easy to loosen and destroy the machine. The fineness of the finished product is the most prominent advantage.